The Executive Summary

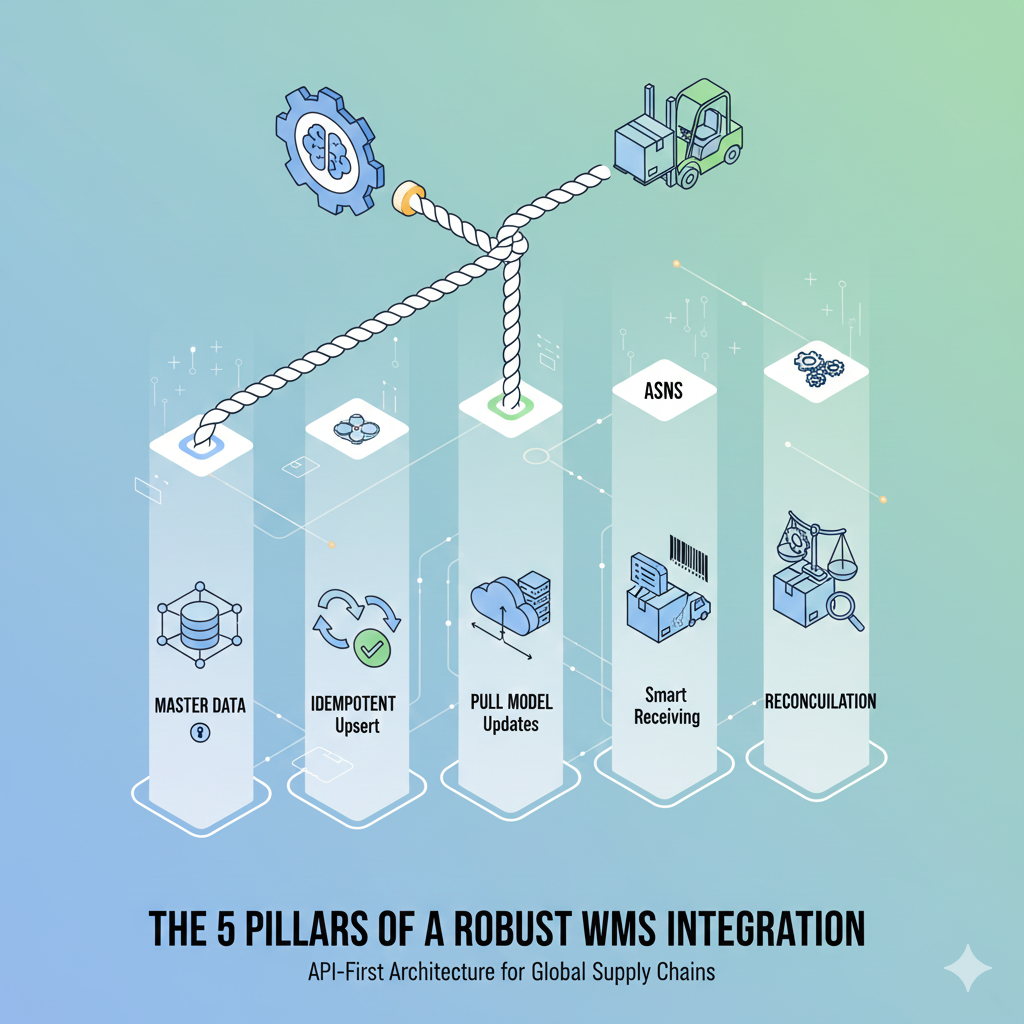

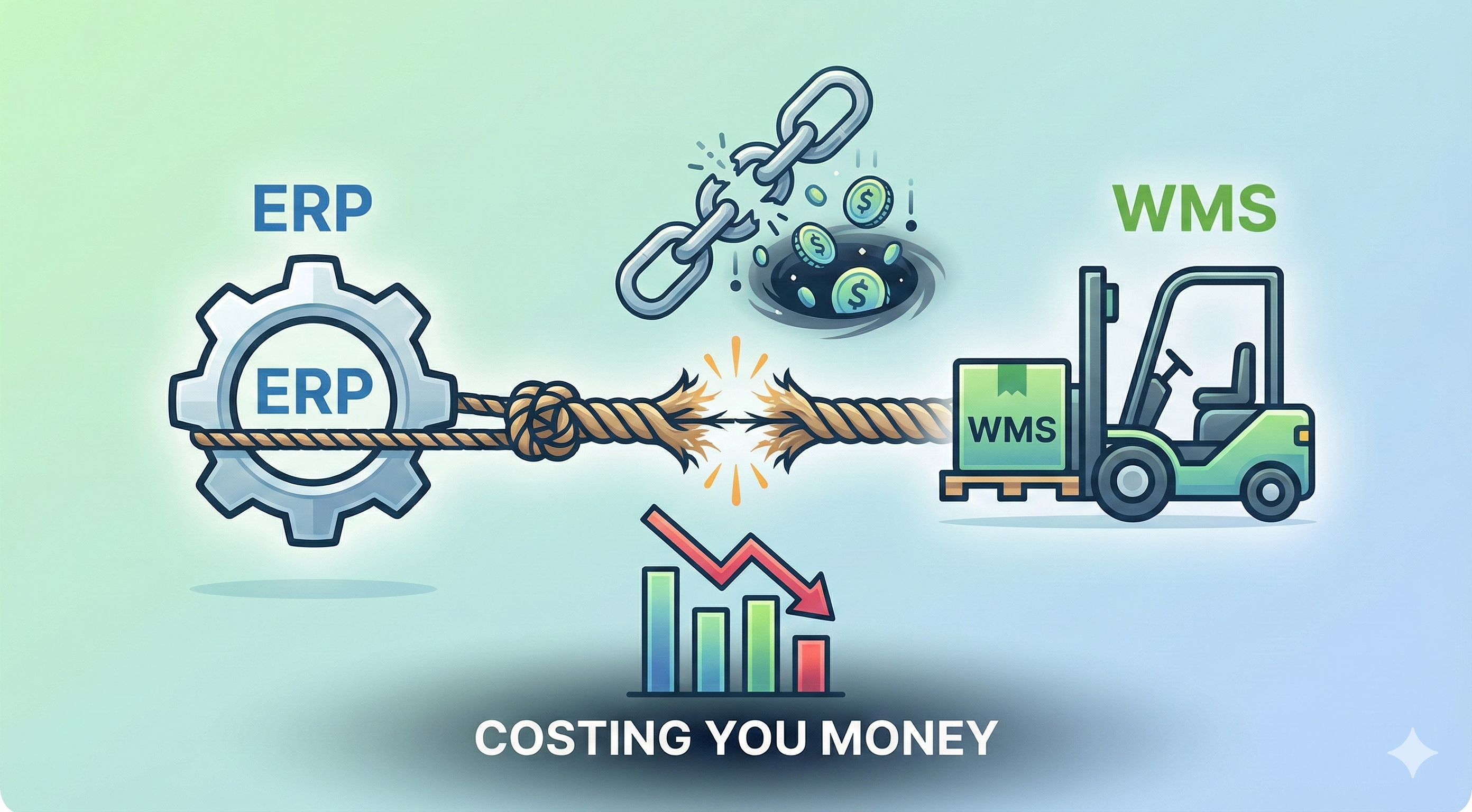

Connecting your ERP to a Warehouse Management System (WMS) is the digital backbone of your supply chain. When it works, it's invisible. When it breaks, trucks stop moving. Drawing from our experience facilitating thousands of transactions globally, we have identified five architectural pillars that separate a fragile integration from a robust one.

1. Master Data is the Prerequisite

You cannot import a Sales Order if the customer or product doesn't exist in the WMS yet. Most integration failures are simply missing data.

✓ The Best Practice

Synchronize master data (Inventory, Customers, Suppliers) before transactions.

⚡ The eveXso Approach

We use a Universal Entity concept for addresses. Whether it's a customer branch or a supplier warehouse, the structure remains consistent, simplifying how data is linked across global systems.

2. Embrace "Upsert" and Idempotency

In distributed systems, networks fail. If your ERP sends an order twice, your WMS shouldn't ship it twice.

✓ The Best Practice

Endpoints must be idempotent—safe to send multiple times without creating duplicates.

⚡ The eveXso Approach

Our API functions as an "upsert" (Update or Insert). We automatically detect if a Sales Order is new or an update, logging every change in a transparent audit trail.

3. The "Pull" Model for Updates

Pushing data in real-time can create bottlenecks. If the ERP goes offline for maintenance, a "Push" model can cause the WMS to hang.

✓ The Best Practice

Use a polling (pull) mechanism where the ERP asks, "What has changed since I last checked?".

⚡ The eveXso Approach

Our ERP_UPDATE_API is designed for batch processing. If your ERP is down, updates queue securely in eveXso until you're back online, ensuring zero data loss.

4. Speed Up Receiving with ASNs

Speed is ROI. Blind receiving (counting items as they come off the truck) is the slowest part of the warehouse.

✓ The Best Practice

Move to proactive receiving using Advanced Shipping Notices (ASNs).

⚡ The eveXso Approach

Suppliers pre-notify the warehouse of incoming shipments via our ASN API. This turns receiving into a rapid "scan-and-confirm" workflow, reducing time on the dock by 50–80%.

5. Trust but Verify (Daily Reconciliation)

Even the best integrations experience "drift" due to human error or timing differences.

✓ The Best Practice

Implement automated daily reconciliation to compare on-hand inventory between systems.

⚡ The eveXso Approach

We provide a specialized 8-step Reconciliation API. It captures a snapshot, accounts for "in-flight" items, and calculates true variance, even auto-generating adjustments within your tolerance thresholds.

The Bottom Line

Whether you're running NetSuite in New York, MYOB in Sydney, or SAP in London, these architectural rules remain the same. A robust integration isn't about perfection—it's about resilience.

Is your integration a bridge or a bottleneck? Talk to Dave about how eveXso's 72+ API endpoints and proven integration patterns can transform your warehouse operations.